- Water cooling build in my wife’s computer – Part IX

- Project Absinthe

- Project Absinthe – Part II

- Project Absinthe – Part III

- Project Absinthe – Part IV

- Project Absinthe – Part V

- Project Absinthe – Part VI

- Project Absinthe – Part VII

- Project Absinthe – Part VIII

- Project Absinthe – Part IX

- Project Absinthe – Part X

- Project Absinthe – Part XI

- Project Absinthe – Part XII

- Project Absinthe – Part XIII

- Project Absinthe – Part XIV

- Project Absinthe – Part XV: It’s alive!

- Project Absinthe – Intermission and future plans

- Project Absinthe – Part XVI

- Absinthe – Part XVII

- Absinthe – Part XVIII

- Absinthe – Part XIX: Valentine’s Day

- Absinthe – Part XX

- Distilling another batch of Absinthe

- Distilling Absinthe – Part II

- Distilling Absinthe — Part III

- Another glass of absinthe

- Another glass of absinthe — II

- Adjusting the recipe

- Absinthe to Amethyst

Finally the day arrives that I can finish tubing out the build. The night before I made sure to get some tubing from Home Depot. In the afternoon I made sure to remind my wife to walk over to the apartment office to pick up the package. All was pretty much set for when I got home. I knew what to do, I knew how to make it happen. It was just a matter of doing it.

Fittings to install. Only one line for tubing needed to be bent and run.

And there were some last minute changes to plans – aren’t there always? So what happened this time?

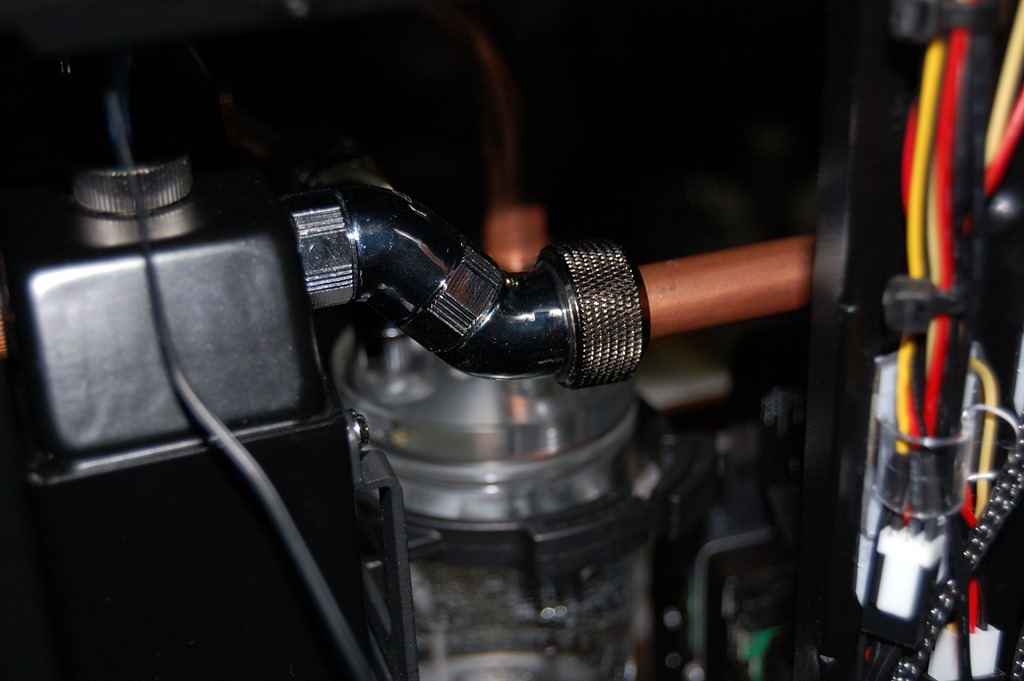

Remember the interesting drainage system I had that would originally have taken the drain through the floor? The 90-degree dual-rotary fitting that curved the flow down to the valve couldn’t get a good seal around the next fitting in the chain for some reason, and it leaked slowly. So I went for a slightly different option while just putting a stop fitting on the bulkhead.

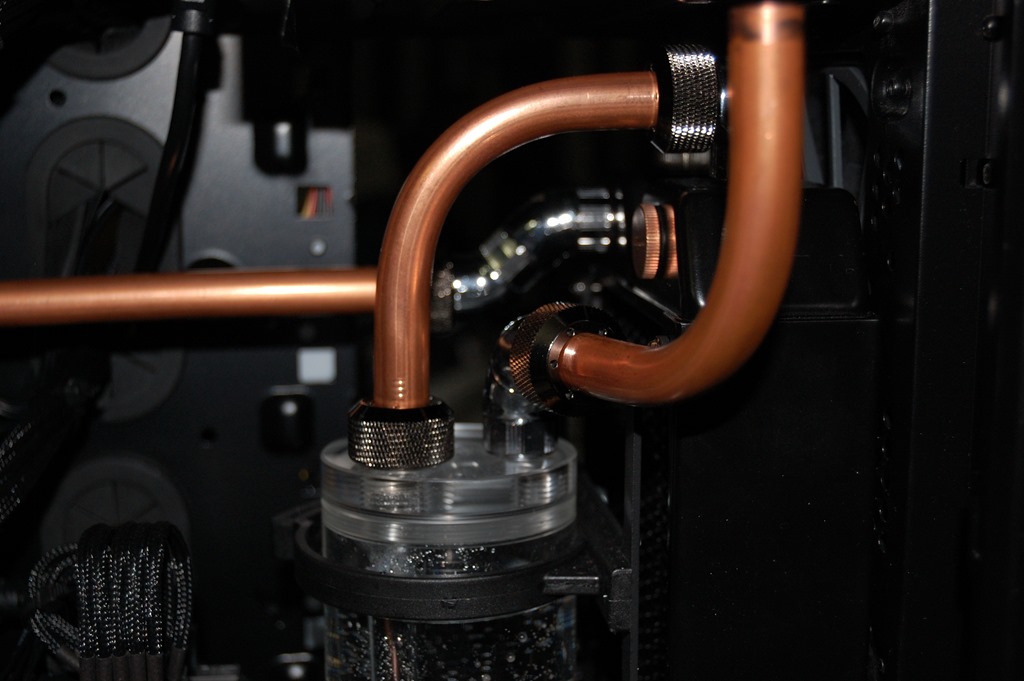

I had already pulled and bent the tubing for the line going to the SLI bridge before doing this, but thankfully it was just a matter of flipping the tubing around. I didn’t even need to run adjust it in any way. Speaking of the SLI bridge…

Recall from the previous iteration on this build log that I had placed an order with Performance-PCs for 5 x 90-degree single-rotary fittings. I needed two for the SLI bridge, one for the CPU block, and the other two were going to be on the radiator. Well there ended up being a small change of plans.

The two 90-degree fittings forming an S-curve of sorts actually put the line too low on the radiator inlet. But I had two 45-degree single-rotary fittings that I tied together to make a dual-rotary fitting and used that instead. Problem solved.

Along with that, the way I was originally going to tube up to the SLI bridge I wasn’t entirely comfortable with, so this turned out to be fortunate. The two 90-degree fittings were moved to the inlet on the SLI bridge to offset it perfectly for the run from the pump. Initially I had the line going parallel with the floor out of the acrylic block fitting and curving up to the SLI bridge. In changing the drainage system, I changed it so it went up from the acrylic block then parallel to the case to meet up with the 90-degree fittings shown above.

The line coming out of the radiator back to the reservoir was pretty straightforward.

The 90-degree tubing on the right is a fill line going into the reservoir. Only temporary.

Once I got the drain port changed over, the leak test went very, very well. Unfortunately it seemed to be taking a while to bleed. Draining it is interesting because of the upright radiator with the fittings toward the top.

But we’re not quite done yet. Next up is pulling this whole thing apart so I can polish the tubing, then re-assembling and doing a quick leak test to ensure everything is how it should be. Then it’ll be filling it back up with the Koolance coolant and doing some temperature benchmarks.