- Beta Orionis

- Beta Orionis – Part II: New fans

- Beta Orionis – Part III

- Beta Orionis – Part IV

- Beta Orionis – Part V

- Beta Orionis – Part VI

- Beta Orionis – Part VII

- Beta Orionis – Part VIII: Delays

- Beta Orionis – Part IX

- Beta Orionis – Part X

- Beta Orionis – Part XI

- Beta Orionis – Part XII

- Beta Orionis – Part XIII

- Beta Orionis – Part XIV

- Beta Orionis – Part XV: Follow-up with Koolance blocks

- Beta Orionis – Part XVI: Overclocking the GPUs (or not)

- Beta Orionis – Part XVII: The AX860

- Beta Orionis – Part XVIII: New power supply and quieting things down

- Beta Orionis – Part XIX: Taking it outside

- Beta Orionis – Part XX: New loop

- Beta Orionis – Part XXI

- Beta Orionis – Part XXII

- Beta Orionis – Part XXIII

- Beta Orionis – Part XXIV

- Radiator box for PC water cooling

- Beta Orionis – Part XXV

- Corsair AX860: A retraction

- Mira

I got to work pretty much right away after picking up the fans from my local FedEx Office. I also made sure to test all of them out of the box with another power supply to ensure none were DOA before installing them. To hold the fans in place, I opted against using the typical self-tapping screws and the included mounts and instead picked up some #8 screws w/ nuts from my local Home Depot.

And I replaced all of the 120mm fans in the system, including the two on the AIOs. And initial temperature testing is acceptable.

I ran Prime95 small FFT for about 18 minutes (long enough for the 28K test to pass on all cores), and the temperature topped out at 60C. It bounced around between 59C and 60C when it topped out as well and there wasn’t any indication it would go any higher. This doesn’t have me very worried as the Prime95 test puts more stress on your CPU than typical unless you’re doing a lot of high-end stuff on your machine – video rendering, 3D modeling and rendering, and so on. Under the stress I typically put my computer, it should stay comfortably in the lower 50s.

It is still significantly higher than with the SP120 fans, so I might change the AIO fan out. Not sure yet.

For the ThermalTake water cooler on the graphics card, temperatures climbed into the 50s with Valley Benchmark. The GPU is one that would need to concern me a little more, though, because games can put a significant load on the GPU, but the temperatures are still quite acceptable. Unfortunately, though, the unit I have has developed a noisy pump, so it will need to be RMA’d to the manufacturer, meaning my graphics card is once again on the stock cooler. I’m thinking this time I might just leave it at that configuration until I start building the custom loop – still RMA’ing the unit since I can repurpose it.

I switched out the fans simply to have a quieter system, and that is certainly the result. I think quieting down the system actually revealed the noise in the ThermalTake’s pump – one good reason to go with quieter fans, as noise from any component is not a good sign.

I expected as well that there would be higher temperatures than with the SP120s. The question was whether the temperatures would still be considered “acceptable”. The CPU is overclocked and cooled only on a single 120mm radiator, and now with a fan that has 10% less airflow and less than half the static pressure of the SP120.

So one question that could be asked is this: if I wanted a quieter system, why did I not just use the 7V step-down adapter that comes with the SP120 and saved the expense of buying the Bitfenix fans? Two reasons. First, these fans will be repurposed into the Zalman Z12 case for a server, which can benefit from the higher static pressure fans – and I’d probably use the step-down adapters there since there wouldn’t really be high-end components in the case. And they likely still would not be nearly as quiet as the Bitfenix fans.

There was a minor hiccup in installing the fans.

The fan filters, Silverstone FF123s, have a curl in their fabric. In the other fan filter I had installed months ago, the curl was toward the magnet side of the filter, with the magnet attaching side attached to the case, meaning it curled away from the fan. In the additional filter I ordered, the curl was away from the magnetic side, meaning it went toward the fan, rubbing on the fan as it spun and creating some additional noise. So consider this when you’re using non-rigid filters like the Silverstone FF123. Just take a glance and make sure any curl in the filter will go away from the fan.

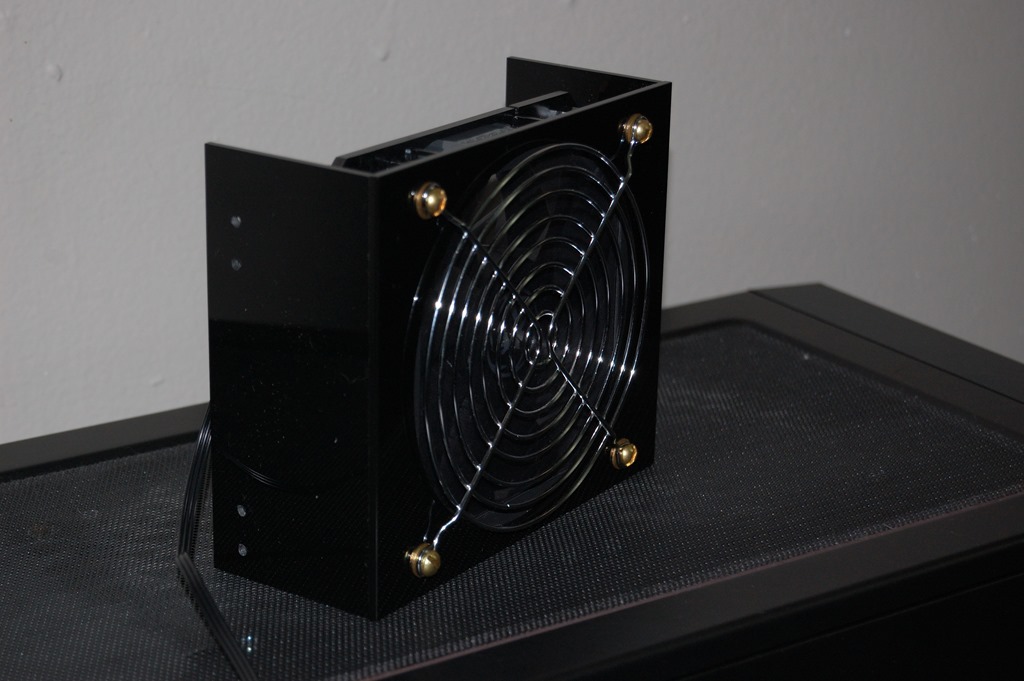

Mountain Mods fan mount

Along with moving the hard drives to an external enclosure, I wanted to do the same with my Blu-Ray writer. External enclosures, though, aren’t exactly cheap. They’re also not really necessary for optical drives. Plug it into a SATA to USB 3.0 converter and you’re pretty much golden, then find a place to put it. Pulling out the optical drive allowed me to pull off the last SATA power line from the power supply as well as remove the last SATA data cable. The case is really starting to look bare, now.

Part of what pushed me to go this route is discovering this:

This is bracket from Mountain Mods that allows you to mount a 120mm fan into 3 x 5 1/4″ drive bays. This one is made of acrylic, though a metal one is also available. The fan is a Bitfenix Spectre Pro 120mm I ordered, and there’s a Silverstone FF123 filter between it and the grill. Unfortunately this doesn’t fit directly into the drive bay courtesy of the support “fins” for the optical drives, but a Dremel took care of that and allowed me to get it in.

But the screw holes drilled into it don’t line up with the drive cage, so I had to use some 3M VHB tape to get it held in place.

I tried using the thinner filter on this, but it kept interfering with the fan, so this’ll have to do for now until I order another FF123.

I’ll definitely be ordering one of these for Absinthe since the fan controller isn’t used, and I’ll just think of something for the temperature sensor so the coolant temperature can be monitored. Perhaps I can make it an Arduino project of some kind. Anyway… This will come in handy for the top radiator in Absinthe to ensure it can get some fresher cool air from the outside. Not expecting a huge difference in temperatures, more just making sure the case pressure stays positive since the front 140mm fans have the 240mm radiator in front of them and the bottom 120mm fans have hard drives (that’ll be changing soon) and the pump and reservoir.

And when I build a server into the Zalman case, I’ll also be ordering one for that as well. That case actually has the benefit of having more than three drive bays, so if I wanted to use an optical drive with it, that’s still an option.

AlphaCool fittings

When I learned that AlphaCool was getting into the hardline business, I was intrigued. They have introduced the least expensive fittings I’ve seen so far, called the AlphaCool HT, which stands for HardTube. Currently they’re only available in black and chrome, and I ordered a pair of the chrome ones to try them out to see how well they’d fit with copper tubing. They’re listed for 13mm OD tubing, and 1/2″ is 12.7mm, so I presumed they’d fit, but wanted a pair to be sure.

This is a compression fitting like the PrimoChill fittings, but they seem to combine both the Bitspower/EK offerings with the PrimoChill offering.

Like the Bitspower and EK fittings, this has an internal O-ring that will seal around the tubing, so whether you’re using copper or acrylic tube, you will likely need to polish the ends of the tubing to avoid damaging the O-ring. Like the PrimoChill fittings, there is another O-ring that goes around the tubing and is compressed on by the collar. And further sealing everything is a rubber washer that goes between the O-ring and collar. The fittings appear to be about the same shape and style as PrimoChill’s Ghost fittings.

Will I be using this to build out β Ori.’s loop? I’m not sure.

I’m stoked about the price: Performance-PCs has them listed at just $6 each, less than the price per fitting of the PrimoChill muti-packs. But the internal O-ring gives me a little pause. When cutting tubing with a tubing cutter, the outside edge is tapered slightly by the cutting blade, but not enough that I’d be comfortable with just reaming the inside of the tubing and using it with these fittings. But having the external O-ring like in PrimoChill’s fittings kind of gives me a little bit of peace of mind. If I end up damaging that internal O-ring, the external O-ring plus rubber washer should prevent any potential catastrophe.

I’ll still need to polish the outside of the cut end just to be safe, but I don’t need to worry about it being perfect. And using just a reamer on the inside to make sure it’s clear of copper filings should also be adequate without having to take sandpaper or a grinder to it.

So we’ll see. It’ll be either PrimoChill or AlphaCool. It’ll be a while before I order fittings – I’ll be ordering the radiators, blocks, pump and reservoir first – so I’ve got plenty of time to make a decision. And it’ll likely be Swiftech for any 90-degree adapters I need, presuming suppliers will have them in stock – everyone including Swiftech are out of stock as of the time I write this. If I need to fall back to something else, it’ll likely be to Koolance.

Come to think of it, I may just go with them anyway – Koolance adapters and blocks, AlphaCool pump and housing, radiators and hardline fittings, and Phobya for the reservoir.